CLIMAtronic™/GPIO v2.10 Build Instructions

CLIMAtronic™/GPIO v2.10 Build Instructions

These are the build instructions for the v2.10 GPIO board from Bowling and Grippo when using it with the VW CLIMAtronic™ HVAC controller. 3B1 907 044 B

No warranty - use at your own risk - Dont Try This at Home - for offroad use

only - may burn your house down and/or damage the planet etc.

You will need the following

GPIO Kit

http://www.diyautotune.com/catalog/g...kit-p-403.html

Parts Kit

http://www.diyautotune.com/catalog/g...ift-p-404.html

The CLIMAtronic head

and a few other bits from wherever you can find them - ebay has the TA8050P

listed

BC327 PNP transistors x 2

IRF9540N P-channel Mosfet x 1

TA8050P H Bridge 1.5A driver x 1

10uf electrolytic cap x 1

Current Version of the Software (right click and save as)

In these instructions, we will build one type of circuit at a time. We start with the base circuits (power, CAN and serial communications circuits), then move onto the input/output circuits: GPOx, VBx, PWMx, GPIx, EGTx, and finally the firmware.

|

HVAC Function |

Processor Port |

GPIO Circuit |

GPIO AMP Connector Pin |

| ac compressor | PE4 | 12v - VB4in - VB3out - compressor | 23 + 35 |

| Keys | PM2 | Climatronic Display | |

| Defrost solenoid | PT1 | PWM4 | 34 |

| Foot solenoid | PT2 | PWM3 | 33 |

| Water solenoid | PT3 | PWM2 | 32 |

| LCD/Keys | PM4 | Climatronic Display | |

| LCD/Keys | PM3 | Climatronic Display | |

| LCD/Keys | PM5 | Climatronic Display | |

| mix servo | PB4 | TA8050P on EGT1 | 22 |

| Antenna | PE0 | EGT2 | 4 not used here |

| Acc Sense | ADO | GPI5 | 27 not used here |

| Exterior Temp | AD1 | GPI2 | 6 |

| Key Sense | AD3 | Climatronic Display | |

| Relay Def/Fan Full | PT6 | GPO3 +12v out | 8 |

| Key Sense | AD6 | Climatronic Display | |

| Face Solenoid | PT0 | VB1 High Current PWM (cruise?) | 11 |

| AD2 | GPI3 Mix Servo Position | 30 | |

| Inside Temp | AD7 | GPI4 and Climatronic Display | |

| PWM Fan Control | PT4 | PWM1 | 31 |

| mix servo | PT7 | TA8050P on EGT1 | 21 |

| Recirc Solenoid | PA0 | VB2 | 12 |

| Key Sense | AD5 | Climatronic Display | |

| Key Sense | AD4 | Climatronic Display | |

| Ign Sense | PE1 | GPI1 | 5 join with pin1 |

| Relay Fan Primary | PT5 | GPO1 +12v out | 10 |

| Climatronic Illum | PWM or 100R ground via EGT4 | 26 | |

| Body CAN High | Expansion | EGT1 U814 via adapt9S12XE CAN1 | 24 |

| Body CAN Low | Expansion | VR2 R60 via adapt9S12XE CAN1 | 15 |

| Drive CAN High | GPIO & R82H via adapt9S12XE CAN0 | 13 | |

| Drive CAN Low | GPIO & R82L via adapt9S12XE CAN0 | 16 |

When you purchase a MegaShift™/GPIO kit, the components typically arrive individually packed, with part numbers. As a result, while you should verify that you have received all you ordered, it is not necessary to identify each item by color, markings, etc.

If you have questions about the specification or appearance of any item, check the part number (listed in {} brackets here) at the Digi-Key site (http://www.digikey.com/) first. Entering the part number in their search engine will give you access to both the catalog information and the data sheet from the manufacturer.

To assemble any of these electronic kits, you will need a soldering iron, some solder, and a few other useful accessories. A 15 watt pencil iron will work fine, however a 25 watt iron heats up faster. Get some small solder. For example, you can use 0.75mm resin solder (~0.030") which really helps to put just the right amount of solder in just the right places. You do not need to use silver solder for MegaSquirt. Make sure to let the soldering iron get hot before using it. A hotter tip makes for quicker cleaner joints, and less heat in the components, because the temperature of the lead reaches the melting point of the solder before the component has had much time to heat up (though letting the iron heat for a while also tends to shorten the useful life of the tip). Let it sit 'powered-up' for 10-15 minutes before trying to use it. The solder should melt nearly instantly if touched to the tip.

Never try to paste solder on a joint using excess solder on the tip. Keep the tip clean, and heat the joint (try to get the tip right at the joint between the lead and the PCB) and hold the solder against the other side of the joint until it starts to melt. Feed in just enough solder to get a bit of a "cone" around the joint, and you are done.

Get a braided copper solder wick as well - you will be glad you did! It is very useful for removing components and cleaning up excess solder. Before plugging in your soldering iron, be sure you read and understand the assembly instructions that follow.

(Note that there is also an excellent tutorial for the assembly of general electronic kits here: www.mtechnologies.com/building/atoz.htm.)

Note: The semiconductor components in MegaShift™/GPIO are sensitive to electrostatic discharge {ESD). To reduce the potential for damage from ESD, some care is needed. Interestingly, you cannot even feel an ESD shock unless the voltage exceeds 3,000 volts, far more than enough to destroy some of the MegaShift™/GPIO components. ESD events do not always destroy an electronic component immediately on the first occurrence, making the eventual failure of your MegaShift™/GPIO very difficult to troubleshoot. Where possible, make use of anti-static controls and material handling techniques, i.e., wrist-band grounding straps, anti-static foam and anti-static bags, grounded workbenches, anti-static mats, etc. Avoid handling semiconductor components more than necessary. If you are not wearing a wrist-band grounding strap, discharge yourself by touching grounded metal before handling ICs and equipment. This is especially important in the winter after taking off or putting on any garments, for example, sweaters and coats. The material of your clothing also has an effect, as materials like silk and some artificial fibers produce a lot of "static electricity". Most commercial carpets contain a high percentage of artificial fibers, which are prone to producing static. Where possible, try to keep the room humidity at 50% or higher to reduce static problems, or use a product such as "Static Guard".

MegaShift™/GPIO; uses a number of components. These components are installed on the silkscreen side of the PCB, and in most case it will be easiest to solder them from the other side of the board. Electrically, the soldering works fine from either side, but as you get more components on the board, it gets harder to solder on the components side, forcing you to use the other side for soldering. There are three ways you can be sure of putting the right components in the right places with the right orientation. Most electronic parts have a standardized scheme for identification.

There are a large number of cryptic designations in building a MegaShift™/GPIO board. Many of these have the form of a capital letter followed by a one or two digit number. These indicate components that are installed on the MegaShift™/GPIO main board (or stim, etc.) and are specific to each PCB. So R9 means resistor (R) number 9. Note that the main board may have an R9, and the stim might too, but they are different. Here are some examples:

A. Base circuits:

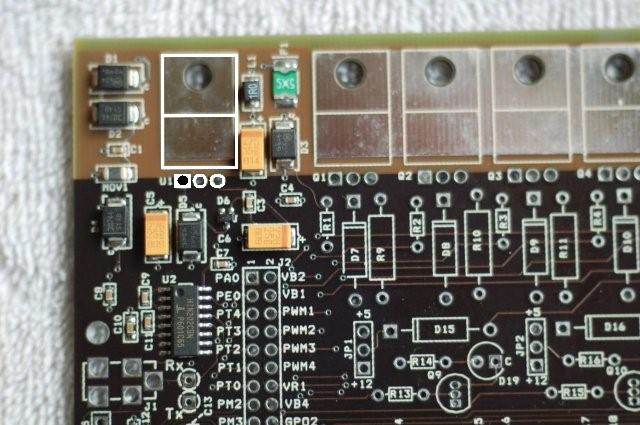

Note that if you wish to mount the GPIO PCB in a non-standard case, three mounting holes are provided:

It has its own location among the SMD components in that corner of the board. You have to bend the leads to a 90° angle so the regulator can site flat against the board, then solder it and screw it the board with a #4-40 nylon bolt and nut (with heat transfer compound (aka. 'heat sink grease') between the regulator and board). You do not need a separate heat sink for the voltage regulator (shown in the diagram below), the voltage regulator can be mounted directly to the PCB (with heat sink compound), as long as you are not using the 5Vref supply for powering off-board accessory circuits.

You have a choice here. You can bring the serial communications out a serial jack (with a 2.5mm mini stereo jack, which is convenient) or you can bring the serial communications out the Ampseal connector (which offers the possibility of weather sealing).

Depending on what you want from your MegaShift™ controller, though, you may end up using the boot header to eventually to load code. To load new code, you put jumper on the two pins on JP5 with no power applied to the board, and once the jumper is in place apply power to the board and use the downloader program.

Some people have put a momentary switch (normally open - NO) across the boot header, and place the switch so they can go into bootloader mode simply by pressing this switch while powering up, without opening the case. (If you do this, be sure it can't be pressed accidentally.)

25x2 Header {WM8135-ND, S9000-ND}:

you must use insulated wire (~20-22 gauge) to jumper:

you could use cut leads wire (~20-22 gauge) to jumper:

Double check that you have jumpered the correct locations.

Note that on the V2.00 GPIO boards ONLY, NOT the V2.10 boards, there are errors on the silkscreen labeling at the 25x2 header, this was corrected on V2.10 boards. The actual circuit connections are the same on both boards, they are just labeled correctly on V2.10+ boards. See this link for more information.

These circuits are arranged in a left-right line just above the center of the board.

Q9 pin1 where 3 should be pin2 in 2 and pin3 in the cpu side of D19

Q10 pin1 where 3 should be pin2 in 2 and pin3 in the cpu side of D20

The pin spacing is very tight on these transistors, be careful not to bridge the pins with solder (use a braided copper wick to remove any excess, if necessary).

Install and solder the remaining two small NPN transistors normally {ZTX450-ND, do not confuse with the 2N3904 transistors that look very similar} in Q14, Q16. These transistors have one flat side with square corners, and one side with rounded corners (this side is marked "ZTX 450"); the flat side with the square corners faces the Ampseal end of the PCB. The pin spacing is very tight on these transistors, be careful not to bridge the pins with solder (use a braided copper wick to remove any excess, if necessary).

These seven circuits are located on/beside the heat sink, nearest the Ampseal connector.

Check the resistance from the TIP120 tab to the heat sink. It should be greater than about 40K Ohms (40000 Ohms), usually higher at this stage. If it is not greater than ~40K Ohms, the mica is not insulating, and you need to find out why (common causes are burrs on the heat sink, missing mica insulators, or missing insulating washers).

Install and solder ONE large TO-220 size P-Channel HEXFET transistor {IRF9540N} in Q7 with insulators {4724K-ND} on the heat sink in positions Q7. These are numbered alongside the 3 holes in the PCB for each transistor. You have to bend each transistor's leads to a 90° angle so the transistor can site flat against the insulator/heat sink PIN3 GETS BENT OUT TO THE SIDE TO CONNECT WITH PIN2 OF Q8 ON VB4. Cut the corners off the mica (nearest the three holes for the TIP120 pins) so that it clears the resistor you will install in the next step. Slide the mica over the TIP120's three pins and place it one the board. Then and screw the TIP 120 to the board with a #4-40 steel bolt, insulator washer (be sure the stepped side is against the TIP120 tab), lock washer and nut (with heat sink compound between the transistor and heat sink and heat sink and board). You may want to put a dab of fingernail polish or something similar on the screw/nut interface to help prevent them backing off due to vibration. Alternately, you can use a nylon bolt without a insulating washer. The nut should be on the top side, to provide clearance in the case. Solder the MJE2955 pins 1&2 from the bottom side of the board PIN 3 FROM THE TOP.

Install and solder the 1.0K Ohm, 1/8 Watt base resistors {brown-black-red, 1.0KEBK-ND} in R19 along with a link from the cpu end of R19 to the bottom of R7.

Install and solder a 330R resistor between the top of R7 and ampseal side of D22 along with a 10K resistor from the top of R7 and the top of D14

Install and solder a small NPN transistor normally {ZTX450-ND, do not confuse with the 2N3904 transistors that look very similar} in Q12. These transistors have one flat side with square corners, and one side with rounded corners (this side is marked "ZTX 450"); the flat side with the square corners faces the Ampseal end of the PCB. The pin spacing is very tight on these transistors, be careful not to bridge the pins with solder (use a braided copper wick to remove any excess, if necessary).

|

Positive is:

|

||

|

Capacitors: |

LEDs: |

Diodes: |

|

The longer lead on polarized capacitors (not all are), sometimes marked with a small + |

The longer lead on LEDs, and the lead opposite the “flat” on the case. If you can see inside the LED, the cathode (which is on the same side the flat would be) is the larger electrode (but this is not an 'official' identification method). |

The end FURTHEST from the band (for forward conduction). |

This circuit is located near the center of the PCB. It is built as a voltage divider (resistance sensing) circuit.

This circuit is located near the center of the PCB. It is built as a voltage divider (resistance sensing) circuit.

This circuit is located behind the center of the Ampseal connector. It is built as a voltage divider (resistance sensing) circuit.

GPI1 (Ignition sense): The input for this connection is paired with the 12v supply at ampseal pin1

This circuit is located behind the center of the Ampseal connector. It is built as a digital input (Voltage sensing) circuit.

This connection is not used in the ordinary 928 Implemetation

GPI5 (Accessory sense):

This circuit is located behind the center of the Ampseal connector. It is built as a digital input (Voltage sensing) circuit.

These circuits are located on the edge of the PCB furthest from the heat sink.

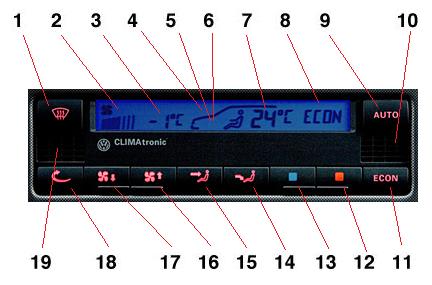

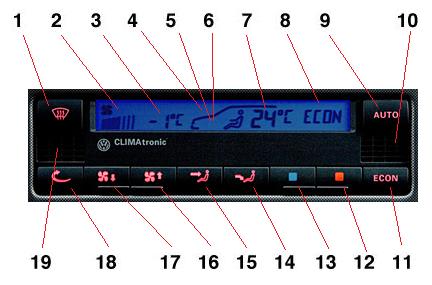

There appear to be two types of CLIMAtronic controller one with a deep translucent rear case and one short and black. The one we want is the translucent case part # 3B1 907 044 B made by Hella.

This circuit is located below the centre of the board. It is built as a digital input (with a pull-down).

yellow - data leads direct to the cpu points on the 25x2 header (i.e pin 2 to AD3, pin 9 to PM7 etc.)

blue - voltage and sense leads to (I used U7 on EGT4 on the board as it has +5v +12v and Gnd etc.

| AD3 | AD4 | PM2 | AD5 | AD6 | AD7 | 5v | |

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| 1 | 3 | 5 | 7 | 9 | 11 | 13 | 15 |

| PM4 | PM5 | PM3 | 12v | egt4 58d- | Gnd |

Modified High side circuits and head/motor controllers

The modifications allow digital control of the servo while still allowing reversal to original operation

I. Vehicle connection and Finishing Touches

There are few more things to do before your board is finished and ready for use:

If there is still haze on the board after drying, or a white residue on any of the solder joints, you should rewash the board until these are completely eliminated. Note that because of the tight spacing of some of the SMD pins, the washing/drying is more critical on the GPIO board than it was on the V3 main board, for example.

You can also buy a spray can of acrylic lacquer conformal coating at most local electronics suppliers for around $10. If you are going to be working the board, “Krylon Krystal” clear spray works very well. Several coatings, preferably baked at 175-200°F degrees in between. This should slow down or prevent "solder bloom" and other deterioration of the PCB. Condensation is a fact of life for an outdoor component undergoing temperature changes. If needed, you can solder right through the Krylon Krystal and the residue cleans well with pure grain alcohol.

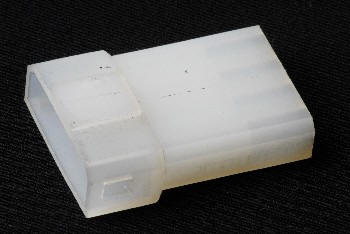

There are two main connections to the vehicle body harness. A 4 pin and a 6 pin version of this connector

|

4 pin |

|

|

|

6 pin |

|

|

|

|

car |

unit |

|

|

car |

unit |

|

1 |

12 v from blower relay |

VB4 (35) |

|

1 |

Power - Ignition |

+12v (1) add pin5 |

|

2 |

AC Compressor feed |

VB3 (23) |

|

2 |

Ground |

|

|

3 |

Outside Temp |

GPI5 or CAN |

|

3 |

Illum |

|

|

4 |

Outside Temp |

ground |

|

4 |

Blower Relay |

GPO1 (10) |

|

|

|

|

5 |

Defrost Relay |

GPO3 (8) |

|

|

|

|

|

6 |

Engine Temp Sensor |

|